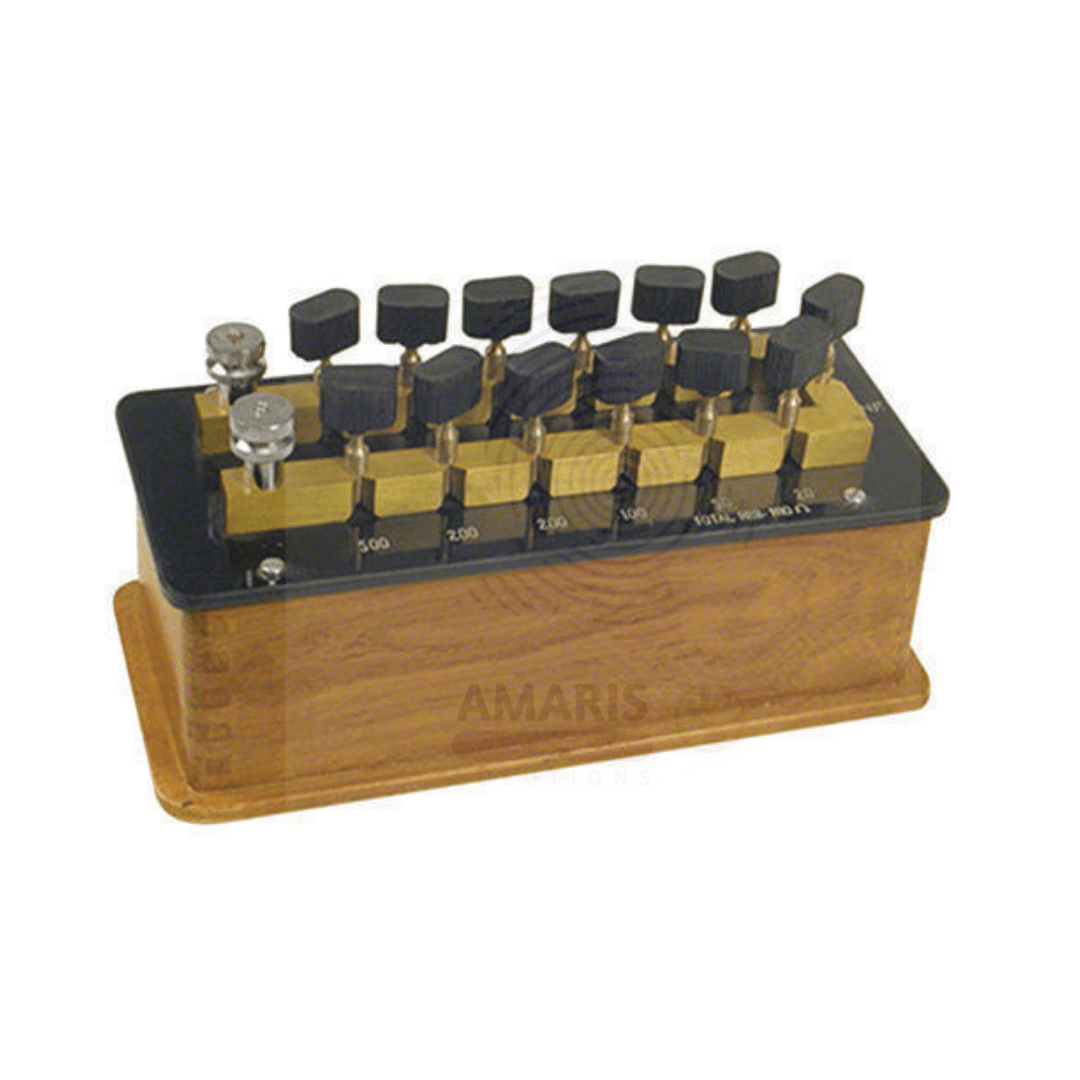

Resistance box plug type

Resistance coil

A resistance coil is a length of conductive wire, typically made from high-resistance materials like nichrome, designed to convert electrical energy into heat through the process of resistive heating. When an electric current passes through the coil, the resistance of the wire generates heat, making it ideal for applications requiring controlled heating. Resistance coils are commonly used in laboratory equipment such as furnaces, ovens, and incubators to achieve precise temperature control for various scientific processes. Their durability and efficiency make them essential for consistent, reliable heating in research and experimental setups.

Retort flask

A retort flask is a heat-resistant, pear-shaped glass vessel with a long, downward-pointing neck, designed primarily for distillation processes. Its unique shape allows for efficient collection and condensation of vapors, making it ideal for separating substances based on their boiling points. The wide base provides stability and facilitates uniform heating, while the long neck helps direct vapors into a receiving container. It is commonly used in chemical laboratories for tasks such as distillation, refluxing, and crystallization, offering precise control over heating and vapor condensation in various experimental setups.

Rhodamine B

Ring and Ball thermal expansion

Rubber Accelerator MBTS

Rubber accelerators are chemicals used in the vulcanization of rubber to increase the speed of the curing process. Vulcanization is a chemical process that converts natural rubber or related polymers into more durable materials by cross-linking individual polymer chains. This process improves the strength, elasticity, and resilience of rubber, making it suitable for various applications like tires, automotive parts, footwear, and industrial products.

Accelerators facilitate the vulcanization process by increasing the rate of cross-linking reactions between rubber molecules. They work by activating the vulcanization agent (usually sulfur) to form sulfur bridges between polymer chains more quickly. This results in a faster curing time and improved properties of the rubber product.